Investment Casting Process

Investment Casting Process(Lost Wax Casting Process)

The investment casting process, commonly referred to as lost wax casting, is a method widely used by the manufacturing industry to create complex and detailed metal parts. In this process, the desired object is first formed by creating a wax pattern (either using 3D printing or through hard tooling), which is then coated with a ceramic material to form the mold. Once the mold is made, the wax is melted and drained, leaving a cavity in the shape of the desired part. Molten metal is then poured into the mold, filling the void and taking the shape of the original wax pattern. After the metal solidifies, the ceramic mold is broken to reveal the finished metal part.

The investment casting process offers many advantages, including the ability to create complex parts with high precision and rich details. While it may involve multiple steps and processes, the end result is a finished metal part that meets the precise requirements of the intended application. Due to the nature of the investment casting process, there is little metal waste, but a small amount of metal can be recycled. The melted wax pattern can also be recycled.

Want to See The Investment Casting Process in Action?

Come into our foundry and watch wax patterns being assembled, wax being dipped into slurry, ceramic coating wax drying in our dedicated drying room, ceramics being fired, molten metal being poured…

Watch our Video Now ›

Explained in 9 Steps

1. Wax Making

Wax replicas of the desired casting are made by injection molding or 3D printing using metal molds. These replicas are called "models".

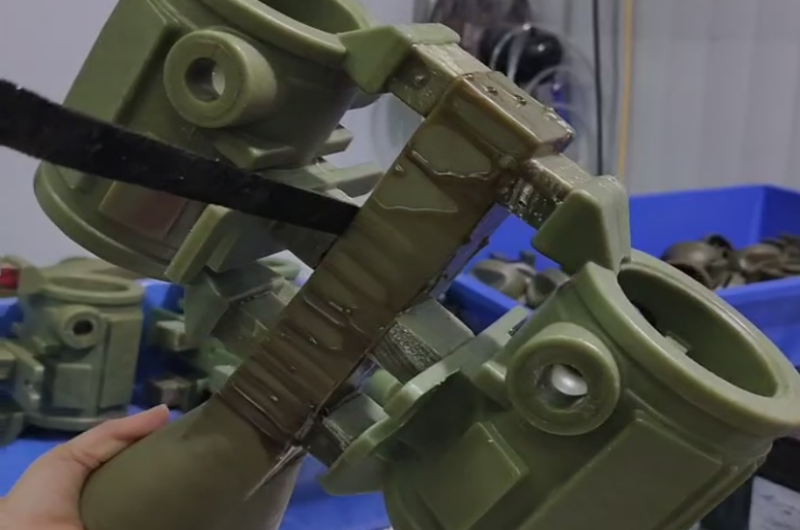

2. Wax Assembly

These patterns are connected to a runner system (called a "tree") via a "sprue" to form a casting cluster or assembly, and mounted on a pouring cup.

3. Investing

The casing is made by dipping the components into a liquid ceramic slurry and then into very fine sand. Multiple layers can be applied in this way.

4. Dewaxing

After the ceramic is dried, the wax is melted in an autoclave to create negative pressure in the shell. The shell mold is then placed in a high-temperature furnace for firing.

5. Casting

The shell is filled with molten metal - metal injection molding is performed using a variety of materials and various techniques, and when the metal cools, the part, sprue, tree and pouring cup become a solid casting.

6. Knock out

When the metal cools and solidifies, the ceramic shell is removed by vibration or water jetting.

7. Cut Off

Use a high-speed friction saw to cut the individual pieces from the center tree.

8. Finishing

Minor finishing operations such as trimming and grinding can produce a metal casting that is identical to the original wax pattern.

9. Inspection

The finished component is then inspected for surface defects and imperfections using gauges, calipers, or a CMM for further analysis.

Tips for Selecting an Investment Casting Process

Investment casting is a very effective manufacturing method that can even produce impressive results. However, the method must be followed rigorously to ensure that the process meets the needs of your project. Here are some tips for selecting an investment casting process, especially when considering Nbcastings Foundry as your manufacturing partner:

1. Evaluate your design needs:

The first step is to evaluate the design of your part. Investment casting is particularly well suited for complex designs that are difficult to handle with other methods. Look at the complexity, details, and features of the design to determine if investment casting is the best choice.

2. Consider the material:

Nbcastings is able to process different types of metals and alloys, so you can choose the material for your project that best meets its needs. When selecting a material, consider factors such as strength, heat resistance, and corrosive materials.

3. Evaluate production volume:

So whether the product quantity is large or small, investment casting is cost-effective in the production process. Conversely, the expenditure on mold making can also be high, which is a more effective way to create efficient wax patterns. Check the production volume and share it with the Nbcastings team to see if the work done fits your budget.

4. Consider delivery time:

Although NBcastings Foundry is known for its efficiency, the investment casting process involves multiple stages that must be completed over a period of time. Be sure to discuss the timeline of your project with the foundry and make sure they can meet the requirements.

5. Review post-processing needs:

While investment casting ensures high surface quality and dimensional accuracy of the product, some projects may require post-processing techniques such as machining, heat treatment, or special types of coatings. These services are provided by Nbcastings – be sure to consult us about your post-processing requirements so that we can meet them.

6. Partner with an experienced foundry:

Nbcastings Foundry is very professional and has a solid background in investment casting. We know how to guide you through this endeavor, providing advice on design optimization and material selection. In addition to providing high-quality results, partnering with a reliable foundry such as Nbcastings will also simplify project management.

Taking these factors into consideration, you can effectively decide whether to use the investment casting process and partner with Nbcastings Foundry. Our focus on quality, customer support, and technology ensures that we are the best choice for your investment casting needs.

Nbcastings Foundry

Nbcastings Foundry is a top custom investment casting and machining manufacturer in China. We can supply a variety of different castings in steel, iron, aluminum, etc.

Please contact us if you have any casting solution needs!

Excellent investment casting Custom parts solutions

Speak to one of our experts today to learn more about our custom casting solutions.