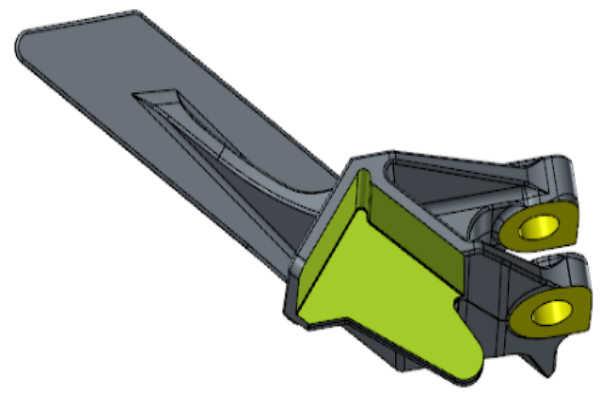

Agricultural Machinery Parts

Product name

Machined castings for agricultural machinery parts

Applicable industries

Mechanical equipment field

Material

42CrMo

Manufacturing process

Challenge

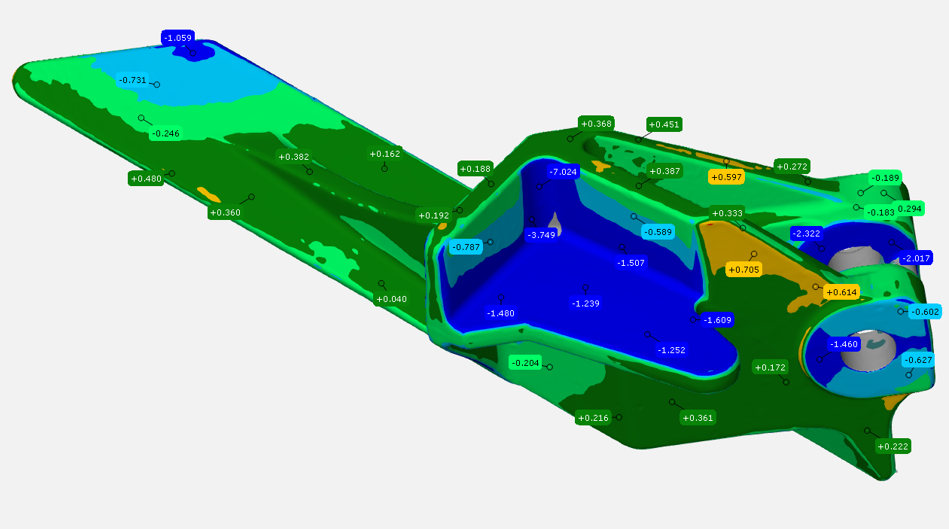

The customer requires the casting tolerance of this part to be CT9. The local machined surface and hole positions must have a contour requirement of 1.5mm and a position requirement of 2.0mm compared to the blank datum. Relative to the product structure, this part is an easily deformable part, and deformation of the casting makes it difficult to guarantee the tolerance requirements after processing.

Need help with a new project?

Let’s push the limits of what’s possible together. Talk to your project solutions expert.

Analysis

In order to make the parts meet the tolerance requirements, we first control the variability area of the casting, determine the shaping method and processing positioning points.

Solution

We add some process ribs to the castings to prevent deformation. For areas where process ribs cannot be set, we make special fixtures to correct the casting blanks. For processing tooling, we adopt 3+2+1 according to the reference points on the drawings, 6-point positioning, and four-axis one-time processing to meet the position tolerance requirements.

Results

We performed 3D scanning to ensure that the model could produce castings according to the specifications specified in the drawings. During processing, we repeatedly and slightly adjusted the tooling positioning points to obtain the optimal state. The contour and position of the processed products measured by three-coordinate measurement can meet the requirements of the drawings.

Excellent investment casting pump and valve parts solutions

Speak to one of our experts today to learn more about our custom casting solutions.