Metal Fabrication

What is Metal Fabrication?

Sheet metal fabrication is the process of forming sheet metal into parts through punching, cutting, coining, and bending.

3D CAD files are converted into machine code that controls the machine to accurately cut the sheet metal and form it into the final part.

Sheet metal parts are known for their durability, which makes them ideal for end-use applications such as chassis. Parts used for low-volume prototypes and high-volume production are most cost-effective due to the larger initial setup and material costs.

Since the parts are made from a single piece of metal, the design must maintain a uniform thickness. It is important to follow the design requirements and tolerances to ensure the part is closer to the design intent.

How is Sheet Metal Fabrication Performed?

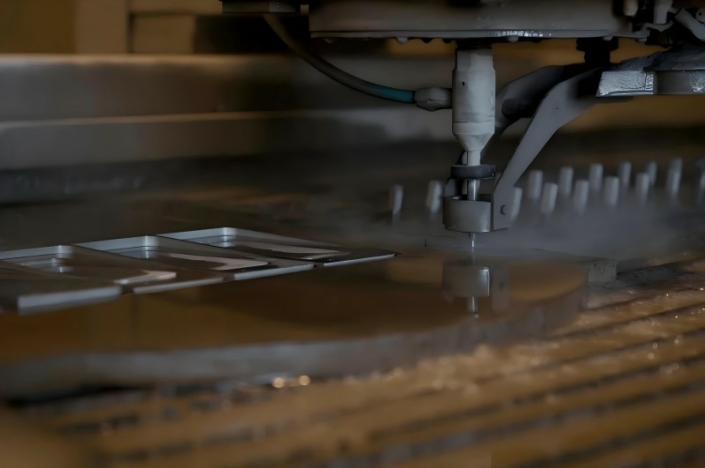

During the sheet metal fabrication process, thin sheet metal stock is placed on a flat plate onto which a laser cutter draws the programmed part pattern. Depending on the part geometry, sheet metal punches can form additional features. After the parts are deburred, they are moved to a press brake where the final geometry is formed. Additional secondary operations are often used to finish the sheet metal part.

Casting Service

Metal Fabrication Advantages

Sheet metal fabrication processes are well suited for metal parts and can support both prototyping and production quantities.

- Less material waste

- Production can be scaled up in an economical manner

- Various surface treatment options, such as anodizing and powder coating

Sheet Metal Fabrication Process

Laser Cutting

Laser cutting is a manufacturing process where a laser beam penetrates a raw sheet to create flat geometric shapes. Available in a wide range of metals, it is ideal for manufacturing parts such as gaskets, brackets, brackets, and housings.

Laser cutting is often used for:

*Prototyping or testing product requirements

*Efficiency of scale up to 50+ parts

*Parts with standard connectivity features (USB, HDMI, Ethernet ports)

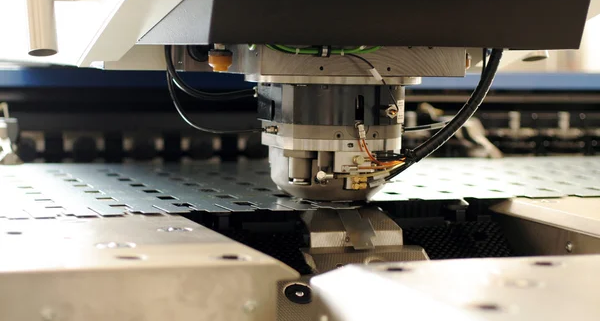

Punching

Sheet metal punching is a metal cutting/processing process in which a punch press uses tools called punches and dies to apply force to the material to create contours, holes, and other formed shapes.

Punching is often used for:

*Functional prototypes

*Product testing and qualification

*End-use production parts

*Bridge production or test runs

Bending

Sheet metal bending refers to the plastic deformation of a metal part along an axis, resulting in a geometric change. The change is only in shape, while the volume of the metal part remains unchanged.

Bending is often used for:

*Brackets

*Busbars

*Cover

*Panels

*Mounts

*Enclosures or housings

Industries We Serve

Nbcastings is proud to provide high quality sand casting services to businesses across a wide range of industries. We understand the importance of reliable castings that will not exhibit any defects during use.

Nbcastings produces near net shape, high quality, durable investment castings for pumps and valves.

Agricultural applications often require looser tolerances, and investment castings have been a major market for this industry for decades.

Our role in automotive precision casting is primarily focused on the aftermarket, or replacement parts that are not produced by the original manufacturer (OEM).

Nbcastings has been producing quality investment castings for companies in the medical industry.

Investment castings used in the oil and gas industry require the highest quality, durability, and corrosion resistance.

Nbcastings has the capabilities and technical expertise to meet the needs of the food processing industry.

Have Questions Left Unanswered?

Nbcastings has many years of expertise in the casting field and can support your project from start to finish. Our team of experts can help you with everything from selecting the right alloy to ensuring the most efficient casting process to meet your specific needs.